By roofers

for roofers

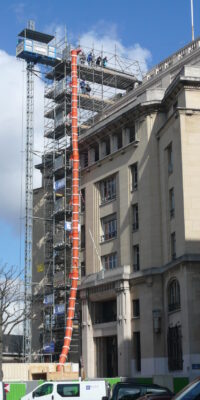

For nearly 50 years, Dimos has supported roofers in France and internationally by offering a complete range of roofing , hand tools, safety equipment, and professional accessories.

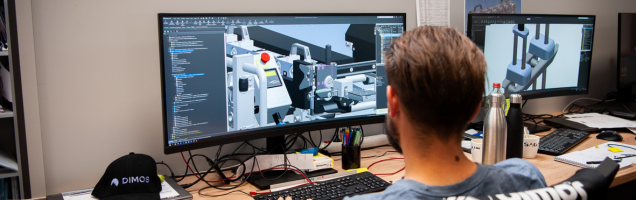

Inheriting expertise passed down through three generations of roofers , we design robust, reliable, and innovative solutions in close collaboration with industry professionals. We also offer specialized training.

Whether you're looking for roofing equipment , precision tools, safety solutions, or practical training, Dimos is your trusted partner for modernizing your business.

Our universes

Experience makes all the

difference.

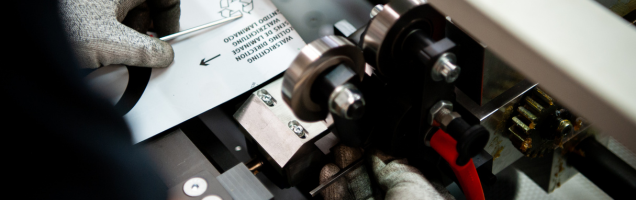

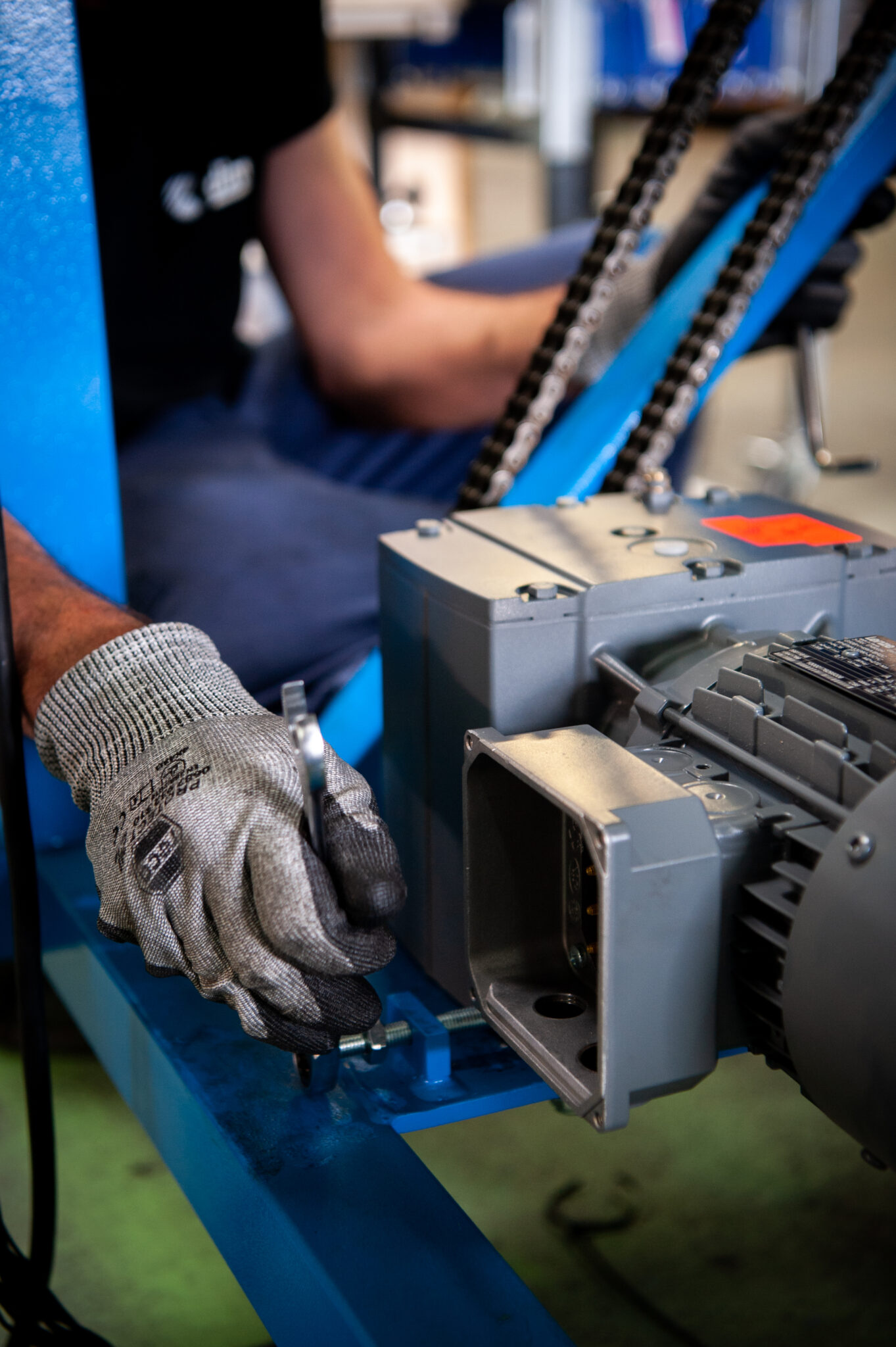

At Dimos , the professional quality roofing tools is not just a promise — it is a concrete reality , validated in the field by thousands of experienced roofers .

Our Roofing Experience Center , located in Ancenis-Saint-Géréon (Loire-Atlantique) 1,200 m² space building and roofing professionals . Open year-round, this unique location offers:

- Technical training of teams through practical demonstrations.

- our cutting, bending and lifting tools under real-world conditions full-size mock-ups.

- The exchange of experiences between craftsmen, trainers and experts in the sector.

Dimos tool ranges are developed to meet the requirements of professionals: robustness, precision, durability and safety on site .

Thanks to our network of partner distributors and training centers throughout France and internationally, you can also find our products in numerous specialized showrooms. Come and try them out, test their performance, and see the added value they bring to your daily work on site.

0 years

Innovation in service of roofers is part of our DNA

0

roofing companies trained by Dimos Formation to operate safely

0

Dimos machines purchased worldwide